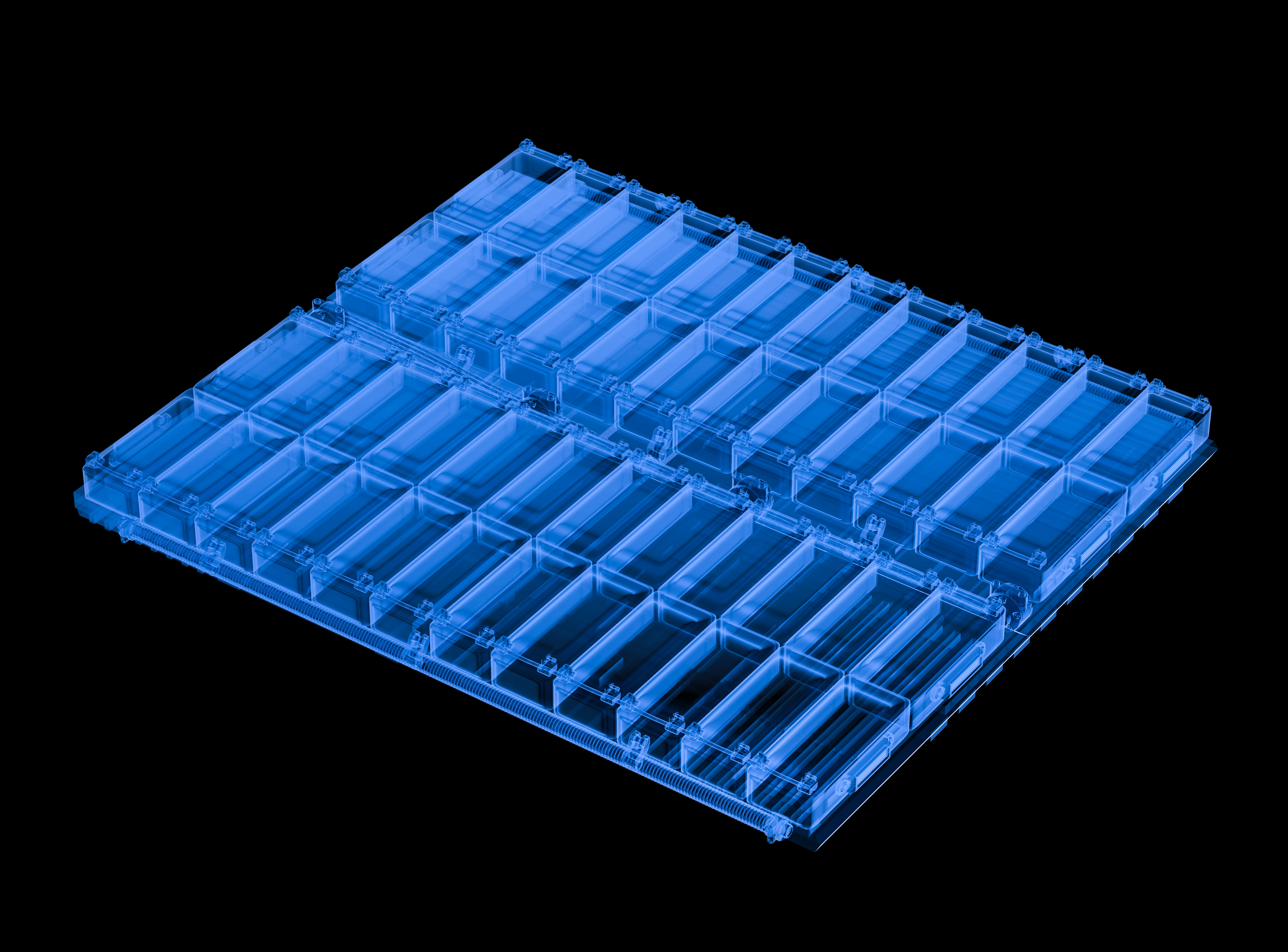

From manufacturing the electrodes to assembling the cells to when the finished product finally takes shape: batteries undergo a series of complex production steps and safety checks before they can be installed. This makes it all the more infuriating when individual batteries have to be rejected during the manufacturing process due to defects, leading to that dreaded word: waste. This not only costs money, but is also seriously detrimental to the environment, especially in view of the numerous rare raw materials that go into making the batteries. What if there were a way to significantly reduce this waste? The answer is inline computed tomography. “Almost every battery produced would then also be usable,” says Steven Oeckl, Head of the Production Monitoring department at the Development Center X-ray Technology.

Optimizing battery production with inline CT technology: Less waste, enhanced quality, and better for the environment

28. Februar 2024 | “Almost every battery produced would then also be usable”

Significantly reducing waste would not only help the environment, but would also boost a company’s profitability. If CT is integrated into the production process at an early stage, it can generally spot defects at a point when discarding rejects is less painful. Moreover, it can also be used to identify which production parameters have led to which quality defects – preventing rejects from occurring in the first place. This works by combining 3D scans of the batteries with neural networks that have been trained on the production parameter data using machine learning. The resulting model catches potential errors before they even occur. “As a result, no energy is wasted on making batteries that would ultimately be discarded,” points out Dr. Steven Oeckl, Head of the Production Monitoring department at the Development Center X-ray Technology.

Reliable test results for sustainable production

Of course, this also improves the safety of the batteries, which can be thoroughly tested with inline CT during the production process. And this in turn increases their service life – another win for the environment. Inline CT provides manufacturers with a tool that automatically optimizes the production process and guarantees batteries of consistent quality. The technology helps them achieve this much faster than trial-and-error methods. This turns battery recycling back into what it should be: the return of batteries to the recycling cycle once they reach the end of their service life, and not while they’re still in production. “Some companies have 20–40% rejects at the start of production,” Oeckl says. In other words, there is incredible potential for inline CT.

What makes the EZRT technology stand out is its focus on making the use of 3D inline CT – often regarded as complicated – straightforward and intuitive. In the future, X-ray inspection will happen completely autonomously – the customer has only to press a button and the system takes care of the rest.

Text by Lucas Westermann, editor, Fraunhofer IIS Magazine