Embedded Intelligent Monitoring

In the European project »SmartFiber« scientists are developing a fully embeddable system for a continuous structural monitoring of composite structures. The intelligent micro systems enable an automated high-performance monitoring in dynamic and hash environments. The project consortium consists of European research institutions and industrial partners including FBGS Technologies GmbH and the Fraunhofer Institute for Integrated Circuits IIS.

The main objective of SmartFiber is to develop a smart miniaturized system for continuous health monitoring of composites which will integrate optical fiber sensor technology, nanophotonic chip technology and low-power wireless technology. Thanks to the innovative approach of integrating micro-technologies, SmartFiber will demonstrate a smart system so small (mm-scale) that it can be embedded in a fiber-reinforced polymer.

The smart system will enable, for the first time, fully embedded structural health monitoring of composites used as structural parts in e. g. wind turbine blades, satellites, airplanes, civil constructions, oil and gas wells, and boat hulls.

With its long term experience in wireless communication systems, Fraunhofer IIS is responsible for the wireless data and power transmission link that will allow the SmartFiber system to work while being fully embedded. The know-how will be complemented by the extensive experience in the field of smart objects accumulated by the Center for Intelligent Objects ZIO at Fraunhofer IIS.

SmartFiber is funded by the European commission within the Seventh Framework Programme EU FP7. It is coordinated by the Interuniversity Microelectronics Centre IMEC, Belgium, one of Europe’s largest research centers for nanotechnology and microelectronics. The consortium comprises the research institutes Ghent University and Fraunhofer Institute for Integrated Circuits IIS, and the industrial partners Airborne, Netherlands, FBGS Technologies (Fibre Bragg Grating Sensors), Germany, Xenics, Belgium, and Optocap, Scotland.

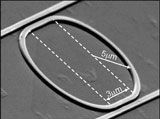

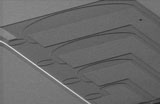

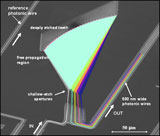

The enabling technology of this smart system is Si nanophotonics, a technology for which imec, in partnership with its associated laboratory INTEC at Ghent University, is world leading. The nanophotonic chip technology enables the realisation of a fiber interrogation scheme or spectral analyser as a photonic integrated circuit (PIC), which has typical dimensions in the order of several hundreds of micrometer. This low-power PIC will be finished by electrical means for wireless communication and inductive power coupling, packaged in a mm-sized cage and coupled to optical fiber bragg grating (FBG) sensors which will be downsized to a diameter smaller than 80 μm. This disruptive approach has the potential to become the enabler for continuous FBG sensor technology in composites and to become the true driver to realise intelligent composites.

The minimally invasive smart microsystems will enable automated high performance surveillance with a prolonged lifetime in dynamic and harsh environments. This will result in extremely improved safety, at economically acceptable cost (automated instead of manual surveillance). Think about wind turbine blade monitoring. The microsystem will enable the turbine to operate much closer to its design limits, increasing wind energy capture and thus electrical energy output. But most of all, it will provide a continuous record of structural data which will inform decisions on maintenance, thereby obviating the need for expensive, periodic maintenance, as well as warning of potentially catastrophic mechanical failures, increasing safety remarkably. The large industrial involvement in SmartFiber is significant. The value chain of the microsystem is nearly covered by the partners’ activities. This strategy gives industrial take-up and commercial development of the technology a huge chance.