At the Fraunhofer IIS Development Center X-ray Technology EZRT, bright minds are working on new ways to ensure that their research and development projects play a pivotal role in climate action. Dr. Steven Oeckl, Head of the Production Monitoring department, says: “For each individual stage in a battery’s life cycle, we have insights and technologies that can benefit industry and the environment. In this magazine series, we’re highlighting specific use cases and taking a look at what to expect in the future. Naturally, we also want this to open up a new channel of communication, so that people who are interested in this topic can get in touch with us.”

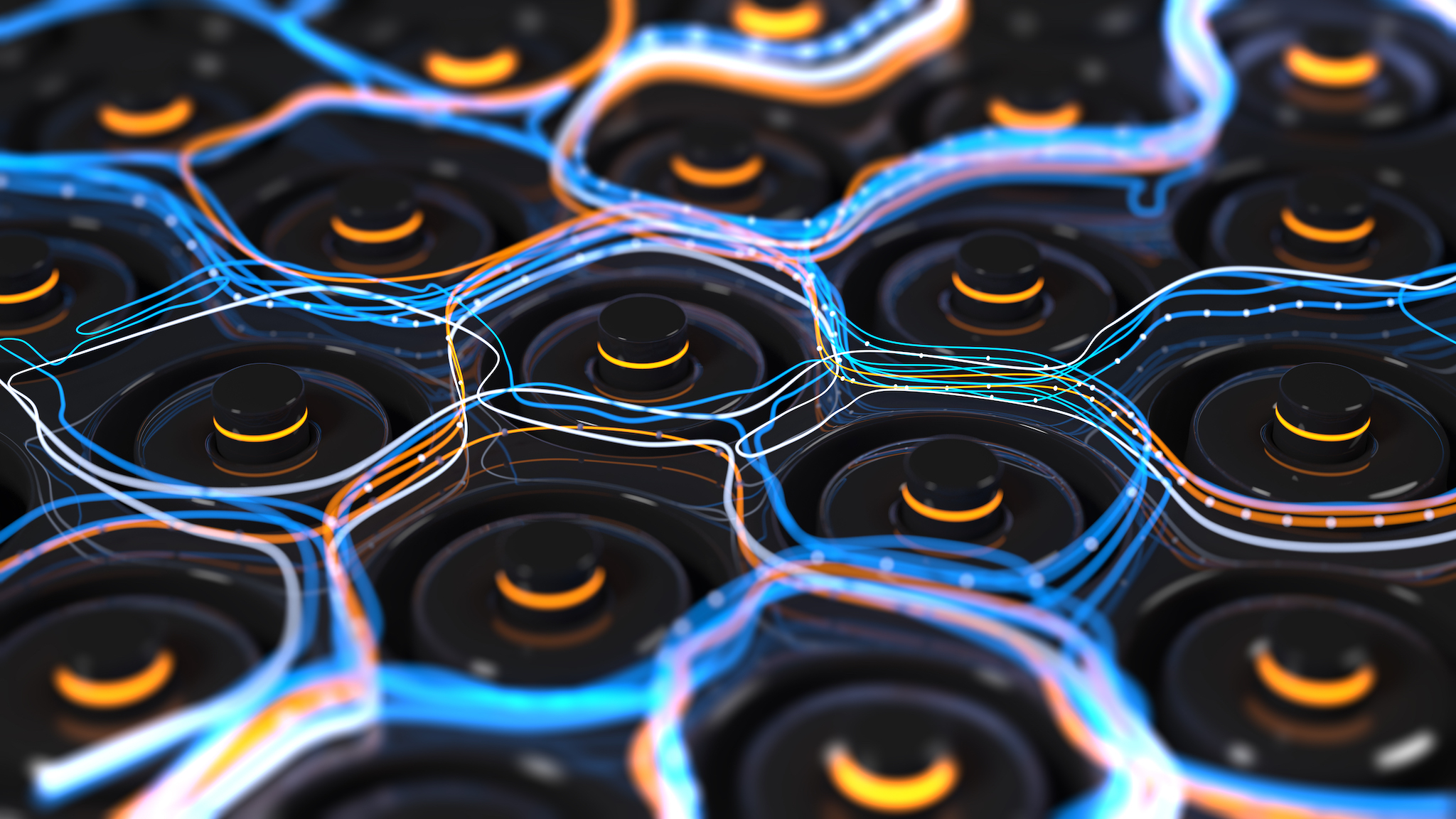

Join us on a journey into the inner workings of energy storage systems, the factories shaping the mobility transition, giant particle accelerators, and microscopic nanoparticles