Why is it important to optimize forklift routes?

Christoph Hohmann: Forklifts are a valuable resource in industrial operations. They ought to be used as efficiently as possible because they help determine whether or not operations run on schedule. To minimize the risk of accidents, vehicles shouldn’t cross paths too often or get in each other’s way.

What forklift data do you collect for this?

We start by collecting data on the status quo: where each forklift is at any time and what load it’s carrying. This allows us to determine how long it took to complete a job, what route it took and when it started the next job. We then generate performance indicators for all industrial trucks, which in turn enables us to ascertain what the utilization was and how efficiently the active time was actually used.

How do you collect data on an entire forklift fleet?

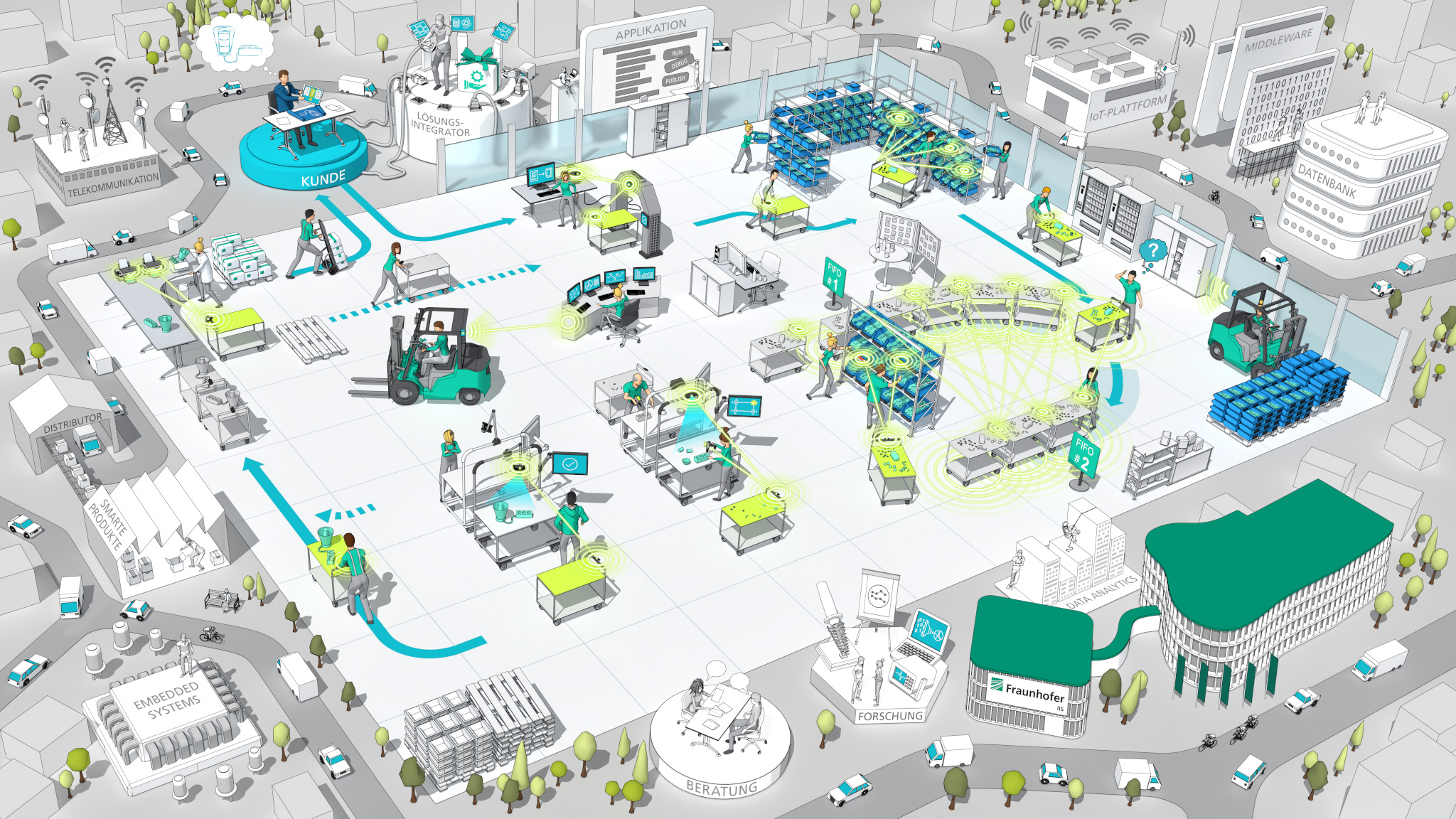

At Fraunhofer IIS, we’ve developed various positioning technologies. We equip the industrial trucks with mobile positioning systems and with sensors. Depending on the customer company’s requirements, we collect data on, say, load status. We track the journeys by running the positioning data through a piece of software that analyzes it to map the respective route and status.

What else can you learn from positioning data on industrial trucks?

The initial analysis of the data shows the utilization of each industrial truck over the entire acquisition period. More detailed observation of each individual vehicle reveals information such as if there were any variations between different days or shifts. If there were, we take an even closer look, applying the performance indicators to determine, for instance, if lead times vary greatly due to overcomplicated loading activities. The analyses depend on solid plausibilities and interpretations of the data collected.

What actions and forecasts can be derived from this and what benefit is there for companies?

First, the current system allows us to perform a comprehensive retrospective review and produce a number of analyses that companies can build on when planning what actions to take. Moreover, we’re currently also investigating how to create lead time forecasts based on real conditions. The data on past operations helps us identify and understand the factors that had an effect on lead times. This means that in the future, will we be able not only to forecast lead times, but also to use these forecasts to take action in time to optimize them.