Successful Research: Trailblazer for Especially Robust Vehicle Electronics

The partners in the research project "RESIST" have spent the last three years working on new approaches to the development of resilient electronic systems. Their results contribute to the next generation of especially fail-safe vehicle electronics to meet the highest quality, safety and performance standards. The work therefore strengthens the competitiveness of German manufacturers and suppliers in the automotive and aviation sectors.

Electronic systems in cars and airplanes are increasingly sophisticated and complex. They are performing an ever-increasing number of functions while becoming smaller and lighter. This increases the performance of the components and allows energy consumption to be reduced. On the other hand, many of the technologies used in the miniaturization contribute to increased sensitivity of electronic components with respect to external influences. This is even more true of the harsh environmental and operating conditions that vehicle components are subjected to. In order to nevertheless satisfy the highest demands on the reliability of electronics in this environment, it is essential to develop new design methods and solutions. Especially for modern, highly integrated systems, an approach focusing purely on robustness alone is no longer sufficient. The objective for safety-critical electronics in particular is rather to enable an early warning system for detection of the "health condition" in order that failures can be identified before failure and corrected, if possible.

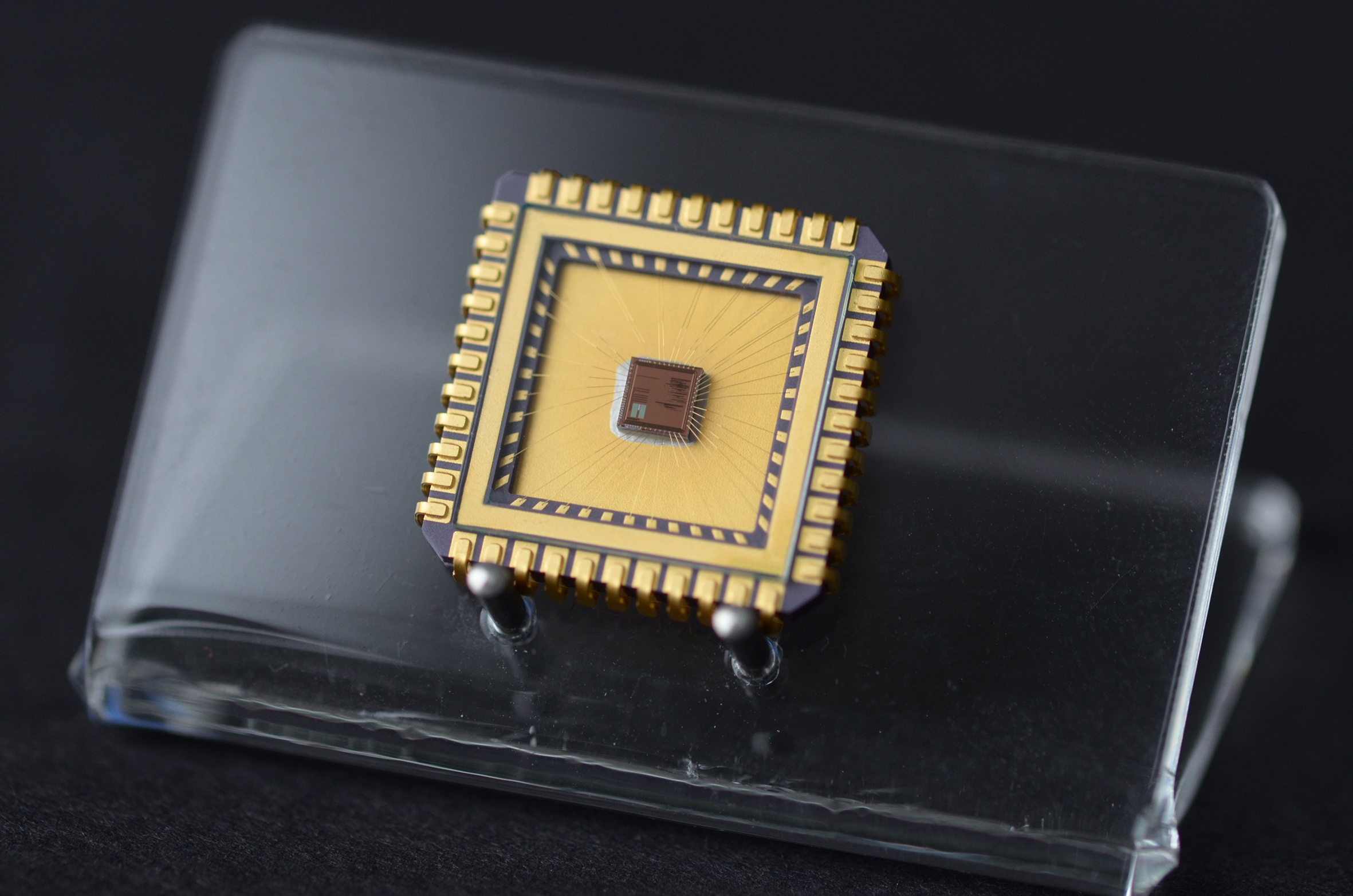

In order to achieve this, the RESIST project partners at the German and European level have researched concepts for designing extremely high-performance micro- and nano-electronic components to be very reliable and robust. The division Engineering of Adaptive Systems EAS of Fraunhofer IIS coordinated the research work into new methods, chip designs and systems in Germany. The RESIST project team consisted of Airbus Innovations, Infineon Technologies AG, MunEDA GmbH, Nexperia Germany GmbH, Robert Bosch GmbH and Volkswagen AG. Reutlingen University, the Munich University of Technology and the University of Bremen are participating as university partners.

Methods and chip architectures for realization of a zero-failure target for vehicle operator

The project work should contribute to extending the lifespan and failure safety of electronic components in future automotive and aviation applications from the current 10 to 15 years to a period of 25 to 35 years. "In order to take all sub-areas of development into account here, the consortium reflects the entire value creation chain," explains Dr. Christoph Sohrmann, project manager at Fraunhofer IIS/EAS. The RESIST partners have developed new types of approaches that permit forecasting of the behavior in subsequent operation already during the design phase of a microchip or a system. For example, this includes new processes that very accurately depict the aging of an electronic circuit to enable a very precise prediction of the long-term behavior. These results can then be taken into account already during the system design. "We not only worked on methodology; we also developed special chip components for further optimization of the results," continues Sohrmann. "For example, the project produced a kind of 'early warning system' in which a sensor continuously monitors the functioning of a circuit. Pending failure due to wear can then be identified early and reported to the vehicle operator or maintenance service." In addition, new types of robust components provide circuits with significant protection against electrostatic discharges that can lead to a reduced lifespan of the electronics. With all measures taken together, components are better able than before to tolerate the operational loads in the vehicle and can therefore function in a fail-safe manner for much longer.

To evaluate the new methods and chip architectures, the RESIST partners tested them in various demonstration projects. Among other projects, a fail-safe direct current converter was created that remained functional even after critical sub-components of its circuit had failed. This ensures uninterruptible continued operation of all electronics and electrically operated safety systems. For the aviation sector, the results were tested in a system for optimized flow control. Distributed actuators enable a highly fail-safe and efficient response by wing surfaces to the prevailing flow conditions.

The work of the German RESIST partners was funded with approximately five million euros by the German Ministry of Education and Research (BMBF) within the framework of the European initiative EUREKA-CATRENE. Their research was embedded within an EU project of the same name, in which additional companies and research institutions from the Netherlands and France also participated. NXP Semiconductors Netherlands was responsible for overall coordination of the work.

Press Contacts:

Airbus Innovations

Daniel Werdung, Media Relations

Phone: + 49 89 607 34275

E-mail: daniel.werdung@airbus.com

www.airbus.com

Fraunhofer IIS/EAS

Fraunhofer Institute for Integrated Circuits IIS

Division Engineering of Adaptive Systems EAS

Sandra Kundel, Communications

Phone: +49 351 4640 809

E-mail: pr@eas.iis.fraunhofer.de

www.eas.iis.fraunhofer.de

Reutlingen University

Johannes Müller, Media Relations

Phone: +49 7121 271 1074

E-mail: johannes.mueller@reutlingen-university.de

www.reutlingen-university.de

Infineon Technologies AG

Oliver Scharfenberg, Media Relations

Phone: +49 89 234 38063

E-mail: oliver.scharfenberg@infineon.com

www.infineon.com

MunEDA GmbH

Harald Neubauer, President & CEO

Phone: +49 89 6227 10220

E-mail: harald.neubauer@muneda.com

www.muneda.com

Nexperia Germany GmbH

Judith Schröter, Marketing Communications Manager

Phone: +49 40 5613 2718

E-mail: judith.schroeter@nexperia.com

www.nexperia.com

Robert Bosch GmbH

Annett Fischer, Spokesperson Mobility Solutions

Phone: +49 711 811 6286

E-mail: annett.fischer@de.bosch.com

www.bosch.com

Technical University of Munich

Ulrich Marsch, TUM Corporate Communications Center

Phone: +49 89 289 22779

E-mail: ulrich.marsch@tum.de

www.tum.de

University of Bremen

Prof. Dr. Steffen Paul

Phone: +49 421 218 62540

E-mail: steffen.paul@me.uni-bremen.de

www.uni-bremen.de

Volkswagen AG

Enrico Beltz, Head of Communications Technology

Phone: +49 5361 9 48590

E-mail: enrico.beltz@volkswagen.de

www.volkswagen.de