The hydrogen-based energy industry is a crucial component in the transition to renewable energy. Hydrogen is relatively easy to transport, can be used flexibly, and is climate-friendly if produced using renewable energy sources.

The hydrogen sector is currently undergoing intensive research to advance necessary technologies and production processes. The goal is to enable the production of components in large quantities, with high quality, and at competitive prices.

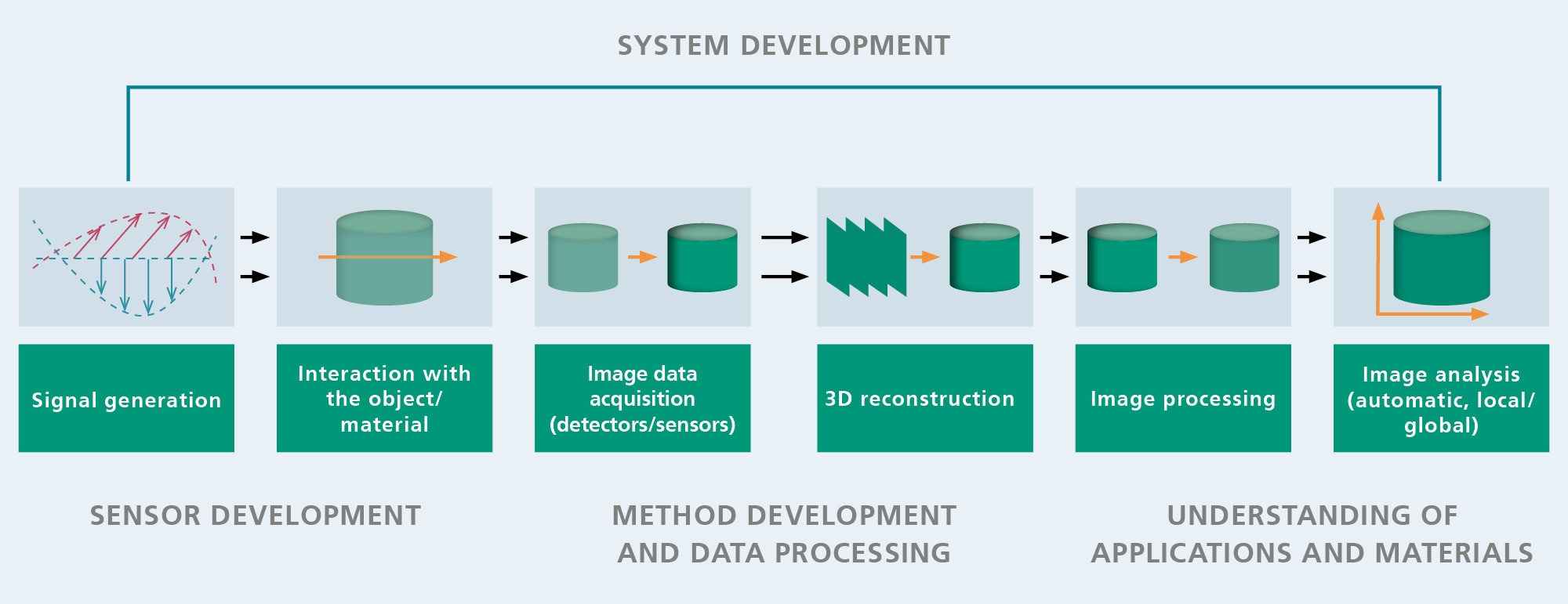

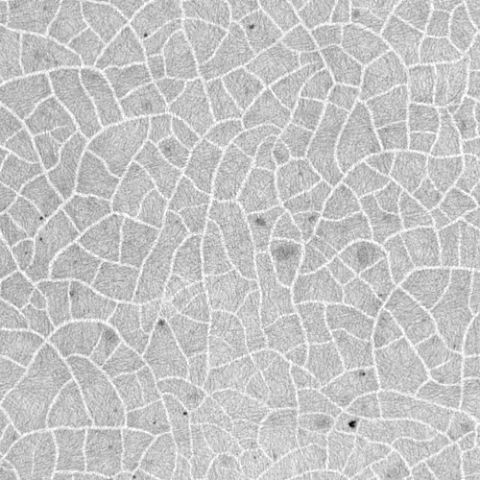

The imaging systems of the Fraunhofer EZRT can contribute both to the development of technologies and processes and to production. They help visualize and analyze the quality characteristics and properties of components.