How the new BM18 beamline is revolutionizing scientific imaging

Grenoble: The electron synchrotron facility in Grenoble has put into operation a globally unique synchrotron-based computed tomography system for the non-destructive testing of large components. Mario Brandenburg (FDP), The Parliamentary State Secretary of the German Federal Ministry of Education and Research (BMBF), opened the new beamline during an official ceremony. The system offers a resolution of 25 micrometers, which puts it well ahead of the previous standard resolution for large components. Through its Development Center X-ray Technology division (EZRT), Fraunhofer IIS is playing a leading role in the development of the measuring station. The project is being funded by the German Federal Ministry of Education and Research with 6.3 million euros.

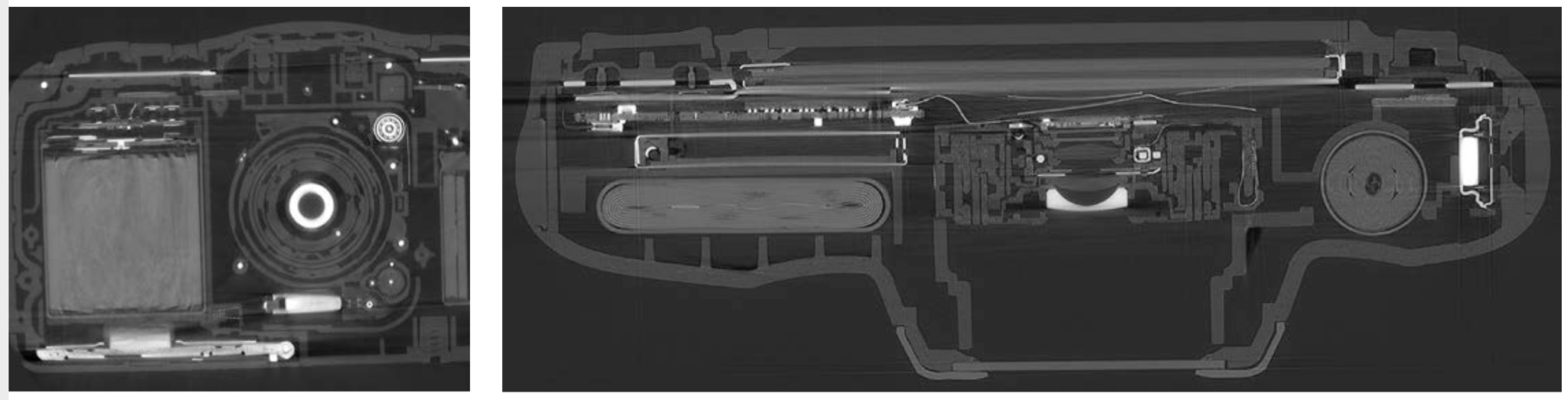

Industrial requirements for component testing are constantly becoming more comprehensive. What is more, there is demand from a wide variety of sectors such as automotive manufacturing, the aviation industry and manufacturers of wind turbines. Manufacturers intend to use computed tomography (CT) for tasks such as assessing the windings of electric powertrains and the integrity of energy storage systems. The CT systems used in laboratories are reaching their physical limits in trying to meet the demand for ever better resolution. The only way to overcome these restrictions is with X-ray systems that are operated at an electron synchrotron installation such as the European Synchrotron Radiation Facility (ESRF) in Grenoble.

Know-how from Fürth for German and European industry

One major novelty and advantage of this complex technology is its easy and straightforward accessibility for industry through Fraunhofer EZRT. Dr. Norman Uhlmann, division director of Fraunhofer EZRT, has been a party to this giant leap forward in computed tomography: “Collaboration between Fraunhofer, an application-oriented research and development institution, and ESRF, one of the world’s leading operators of synchrotron systems, permits the use of this globally unrivaled industrial CT beamline. The potential benefits of this for German and European industry are enormous.”

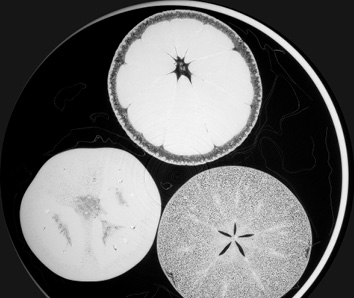

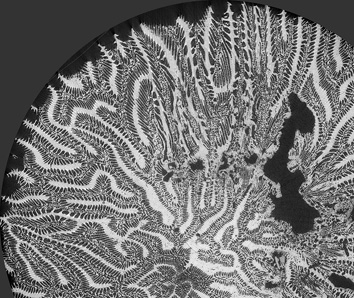

The new system is revolutionizing scientific imaging and opens up new potential applications in various fields, including medical imaging and bioimaging, the material sciences and research into new materials. It enables biomedical researchers, for instance, to characterize the complete anatomy of human organs in 3D down to the cellular level in order to better understand diseases such as COVID-19, infections or neurodegenerative illnesses. It also offers new possibilities for industrial research, as large components can now be examined for microscopic defects, enabling design improvements, for example in aviation or the automotive industry. This applies to fully assembled objects as well: individual components can now be inspected without disassembling the object.