More security for airfreight

Nuremberg (Germany): Each year, the airfreight industry suffers hundreds of millions of euros in losses as a result of unauthorized openings, unmarked hazardous substances, and the manipulation of goods. The CairGoLution project, headed by the Fraunhofer Institute for Integrated Circuits IIS, has facilitated the development of a technology-based security service ensuring the secure transport of goods in the airfreight logistics chain. The first test flight with an intelligent airfreight container was successfully completed in January 2017.

Along global airfreight logistics chains there is a risk of packages being opened without authorization, of hazardous substances being imported, and of manipulation to the unit load devices (ULDs) used for storing goods during the flight. The loss and repairs of ULDs alone result in damages estimated at some 270 million euros each year. A significant prerequisite for ensuring secure transport from the sender to the recipient is the continuous status monitoring of goods and load carriers.

Real-time monitoring of the airfreight container

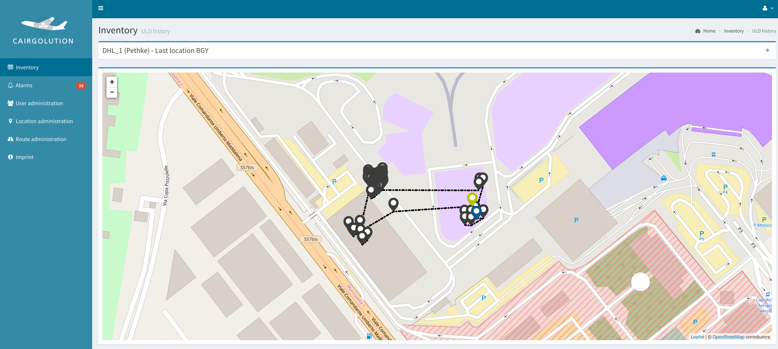

In the CairGoLution project, the combination of Telic AG’s specifically developed asset-tracking systems and Fraunhofer’s s-net® networking technology guarantee secure monitoring and geolocation of the freight. “A ULD monitoring system uses sensors to reliably recognize unauthorized access to the ULD, and to create and transmit an alarm notification in real time for those responsible for the shipment and for the relevant authorities,” explains Tobias Seidler, project manager for the Supply Chain Services team at Fraunhofer IIS. “This allows for the creation of new security services based on telematics and sensor data, thus achieving the secure monitoring and geolocation of airfreight containers.”

To maximize the period of operation in the field, Fraunhofer IIS developed a special energy-harvesting module that can obtain power from minimal sources of light. Furthermore, the Fraunhofer Development Center for X-ray Technology (EZRT) devised a software-based solution that uses X-ray signature comparison to identify breaches of integrity in the airfreight logistics chain. To ultimately make the security service visible to the user, Fraunhofer IIS then handles the integration, analysis and processing of the data based on Kentaur, the server communication software utilized by Telec.

The security of the data was ensured in particular through intelligent dynamic encryption processes that offer a very high standard of security without unnecessarily increasing the transmitted data volume relevant for mobile communications.

Special provisions for airfreight

The major challenge in implementing the continuous status monitoring of the ULDs was that – in contrast to solutions in road, rail and sea transport – the applied technologies are not allowed to actively transmit data continuously. During the main leg of the logistics chain, the ULD is generally in an airplane’s cargo hold. The technologies utilized for status monitoring have to be passive during this particular phase.

The concepts and realization of the technology for automatically deactivating all radio modules during a flight were developed as part of the research phase and integrated in Telic AG’s asset-tracking systems. The necessary tests and measurements were conducted successfully, thus complying with the requirements of the air traffic authorities.

First test flight confirms feasibility

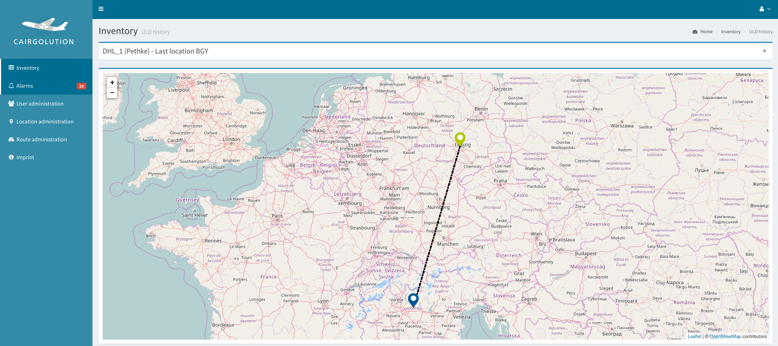

The first intelligent ULD started from the DHL hub in Leipzig on January 18, 2017, for a flight to Bergamo. This first field test of the logistics solution was based on the qualification tests for compliance with RTCA DO-160G. The assessment of the data showed that the ULD suffered no breach of integrity on its trip from Leipzig to Bergamo and on to Naples, then back to Bergamo. Further data for the ULD could also be evaluated in the CairGoLution portal, including the duration of the individual stops and the transport times. Besides the technical challenges, the test also documented the efficiency of the fully automated process of tracking airfreight containers. The telematics modules are designed for extensive operating times and maintenance-free continuous operation of at least seven years.

Live operation beginning soon

The CairGoLution project provides access to a geolocation and monitoring solution for airfreight – one that is operational and approved. The further development of the system for live operation is expected soon. This will enable the continuous tracking of valuable and time-sensitive goods along the supply chain, from the sender to the recipient. CairGoLution enables the integration and interpretation of telematics and sensor data for the expansion of services; this can be used for further areas of application, such as the transport of medications.

CairGoLution has been a joint project carried out by Fraunhofer IIS with the express delivery service provider DHL Express and with DHL Smart Sensor, Telic AG, DoKaSch GmbH, and research partner TU Darmstadt. CairGoLution was sponsored by Germany’s Federal Ministry of Education and Research (BMBF) and is part of the framework program “Research for Civil Security.”