The complete X-ray inspection of fully assembled vehicles can currently only be carried out under laboratory conditions at a few locations worldwide - including at the X-ray Technology Development Center at Fraunhofer IIS using XXL computed tomography. However, the procedure is complex and costly, so its use is currently reserved for companies that check safety-relevant components in particular during the development process.

The newly developed AIR system (traction battery inspection using X-rays) changes this: the system makes it possible to visually assess the mechanical integrity of battery modules by taking an X-ray image of the vehicle and the traction battery mounted in the underbody. To do this, the vehicle is driven into the measurement system - the measurement setup is reminiscent of a classic car wash.

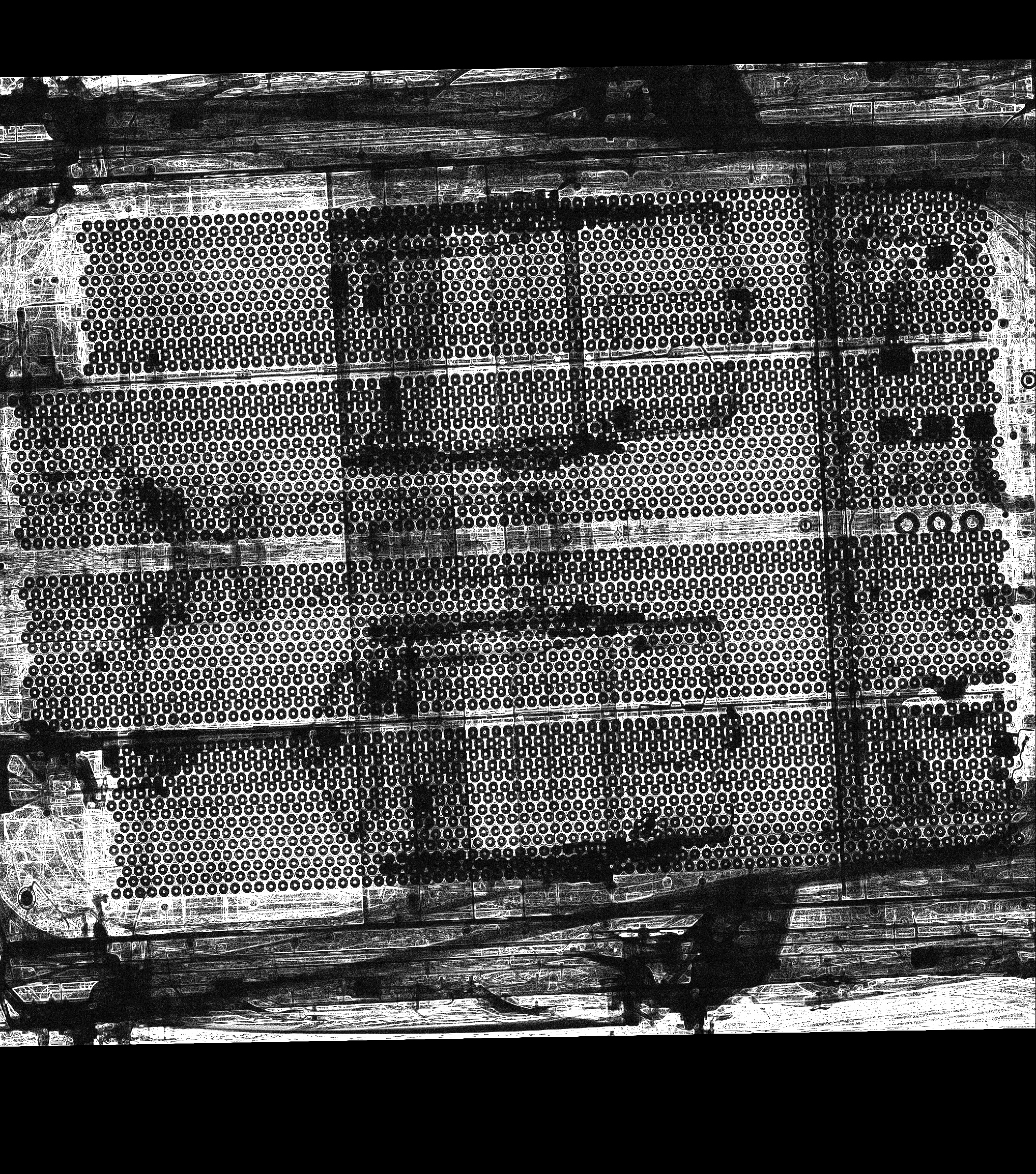

The X-ray images are taken from a bird's eye view. The X-ray source positioned above the vehicle emits a fine X-ray beam that passes through the vehicle, including the battery, and is collected and processed by a detector positioned on the ground. Even in fully encapsulated battery modules, a detailed view of the battery is possible in order to make statements about the mechanical condition of individual battery cells, the battery frame and other features. This information can be used, for example, to analyze and evaluate individual components of the vehicle or battery with regard to position, alignment or integrity.