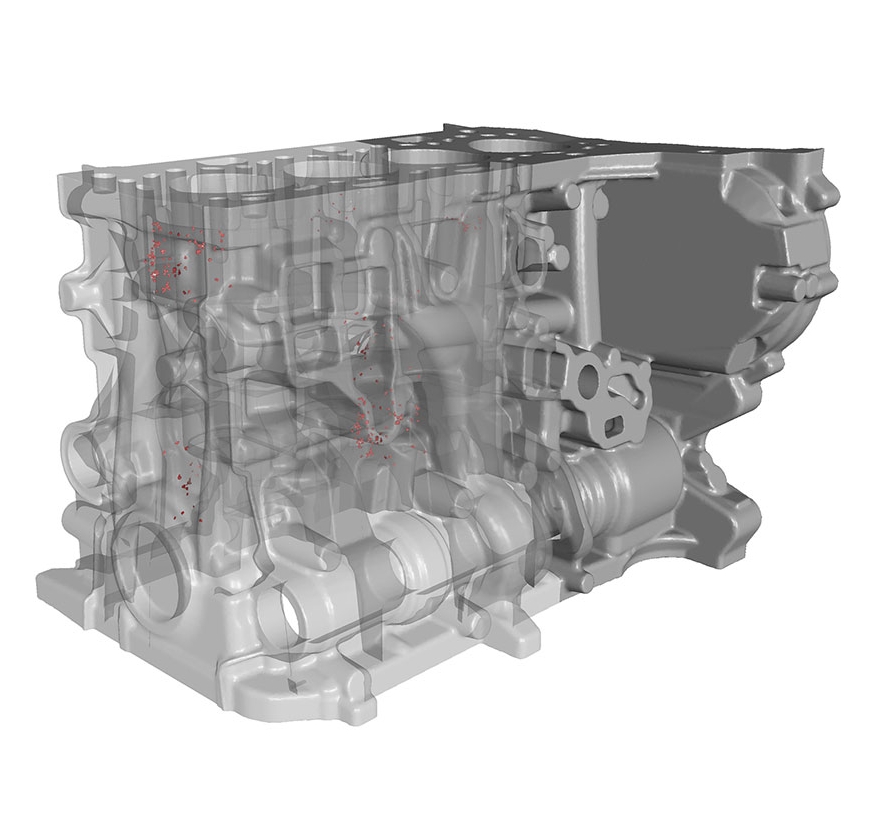

We are developing inline computed tomography systems (inline CT systems) for production monitoring, which can detect deviations from the optimal production process at an early stage to minimize rejection rates during production. Casting defects, such as voids or pores, are not only detected, but precisely located and analyzed. So even components with abnormalities, which were previously treated as rejects due to lack of information, can be further processed if the abnormalities are in a non-critical area or the region is machined later. In addition, the obtained metadata is fed directly into the manufacturing process. Thanks to intelligent data feedback, production parameters such as pressure or temperature can be set so that critical defects do not even occur.