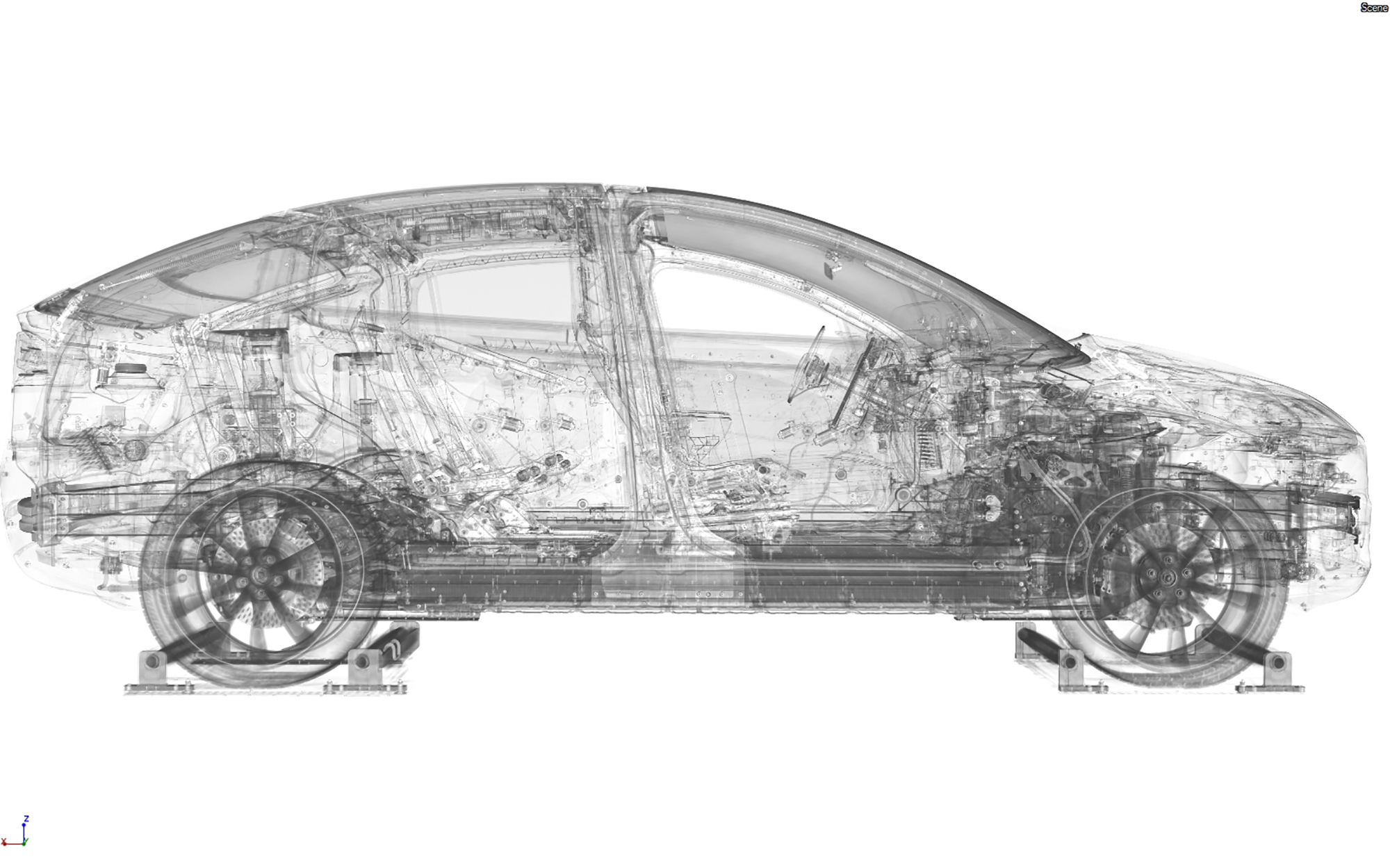

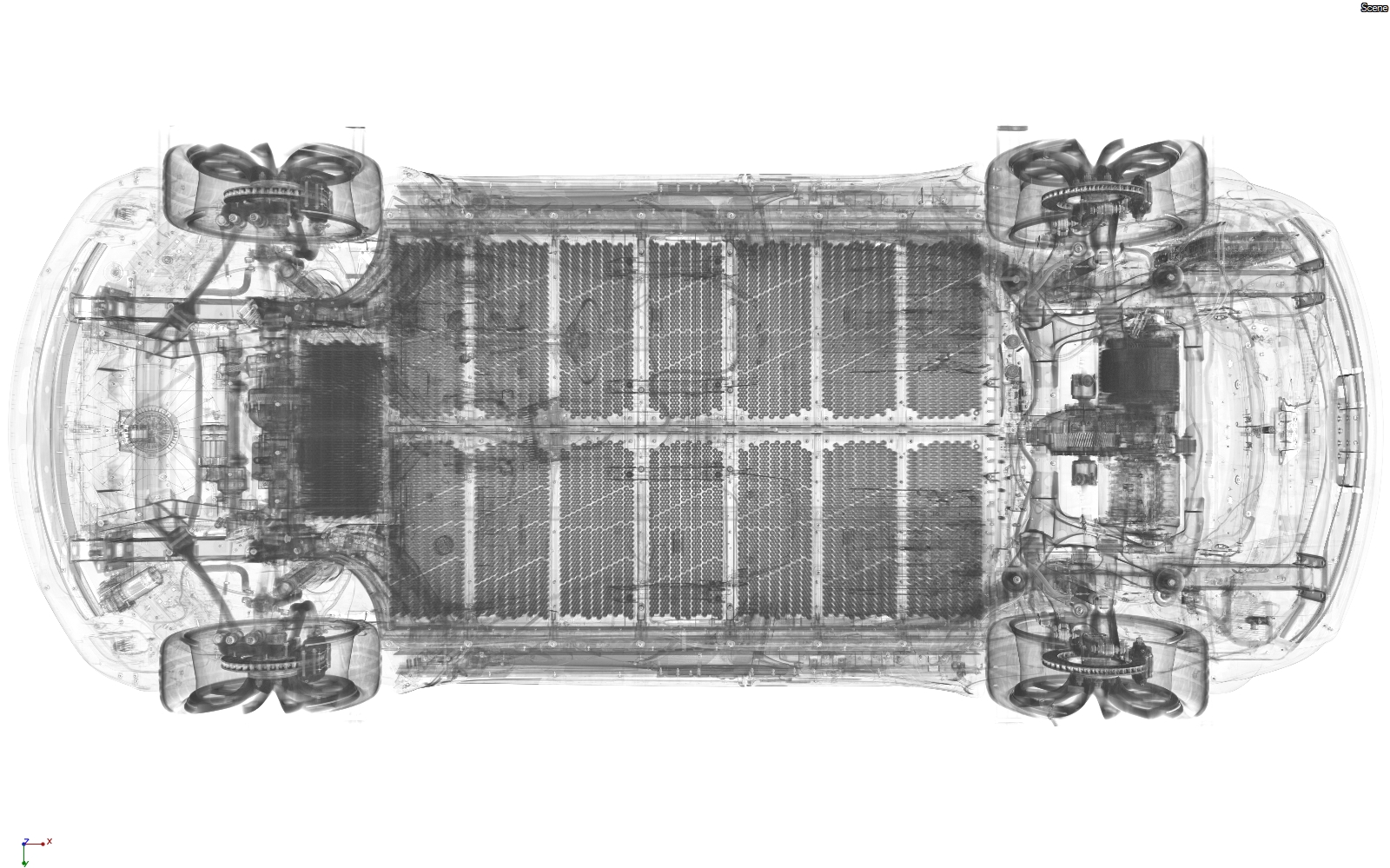

The XXL CT in tower design, which went into operation in 2013 and is the only one of its kind in the world, took computed tomography to completely new object dimensions. For the first time, it was possible to tomograph complete vehicles three-dimensionally and in sub-millimeter resolution.

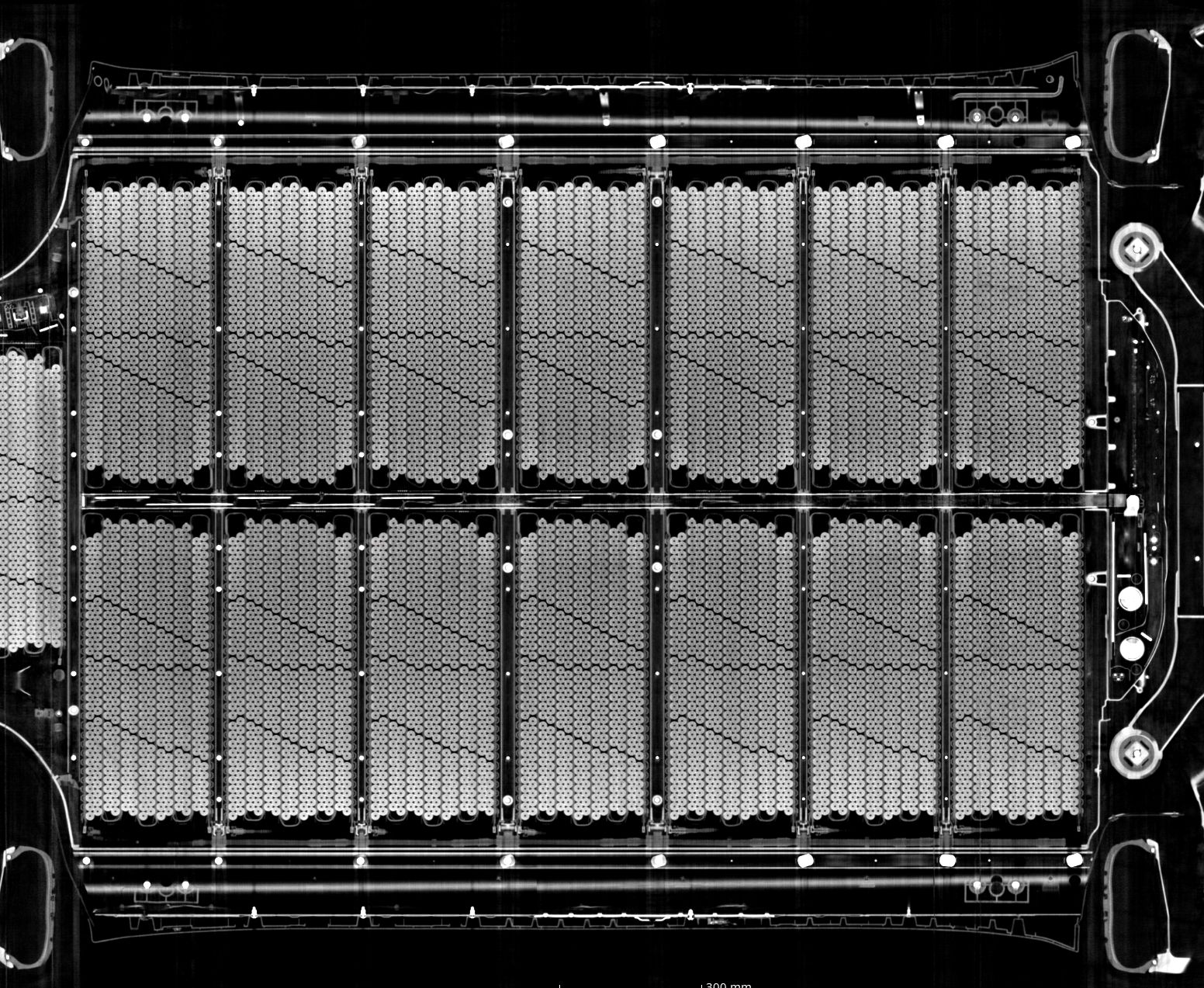

With this extraordinary laboratory system, numerous projects have been realized in recent years that would previously have been unthinkable: in addition to a large number of vehicles and vehicle components such as high-voltage storage units, entire aircraft (Me-163) as well as entire sea freight containers and much more have already been digitized in three dimensions.

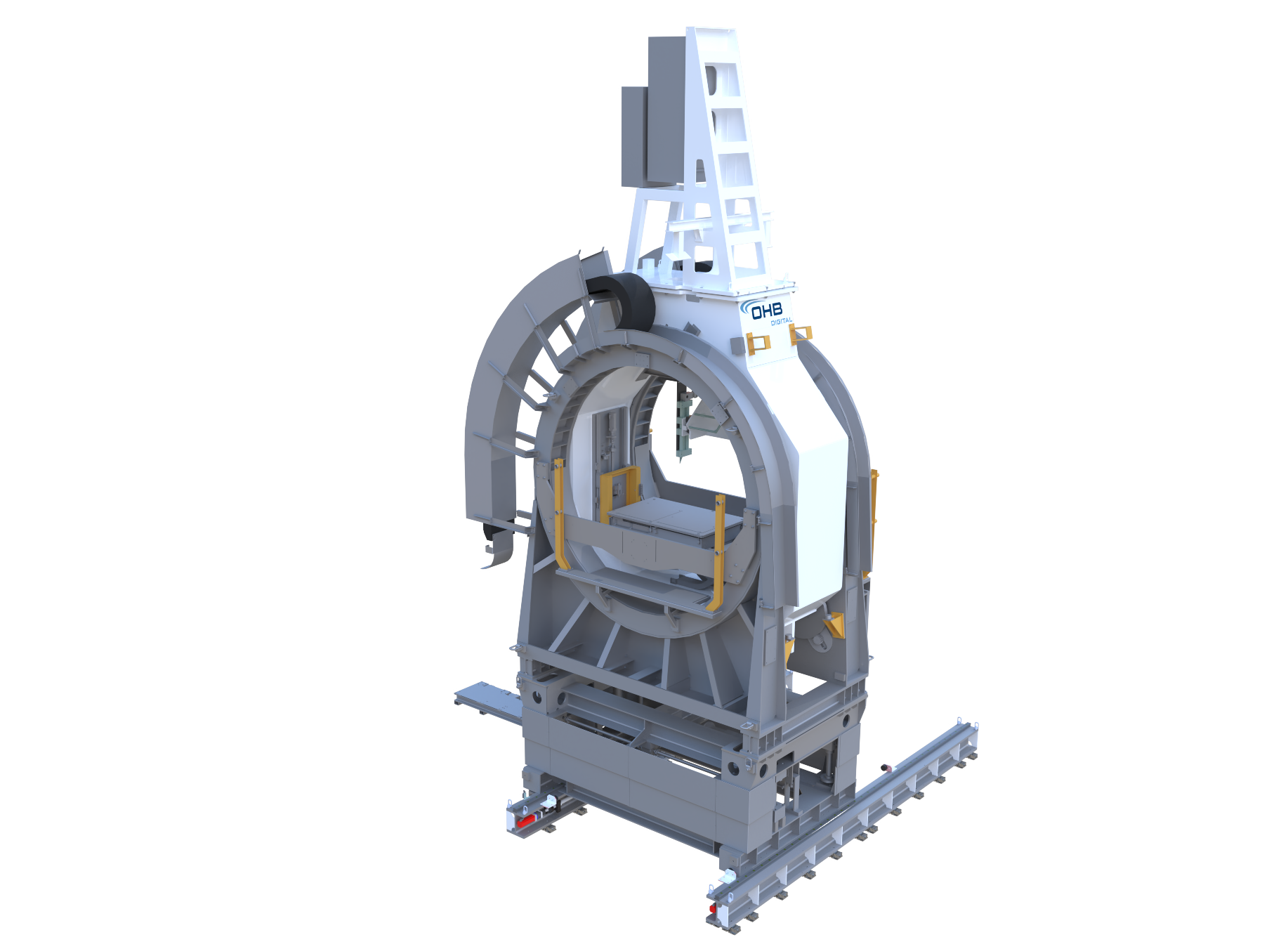

The GiantEye system architecture, developed from scratch together with OHB Digital Connect, is based on many years of experience in the field of XXL CT and represents the next generation of XXL high-energy CT systems.

The system geometry in so-called gantry design is reminiscent of an oversized medical CT system, in which the radiation source and X-ray detector rotate around the object being measured.

This offers the great advantage that particularly long objects, such as vehicles, no longer have to be scanned in an upright position, but can be scanned in their natural orientation, i.e. in the »road position«.