In two-dimensional X-ray analysis, or radioscopy, an X-ray source is emitting X-radiation, which penetrates objects. Depending on the material and wall thickness of the test object, this radiation is attenuated. An oppositely mounted detector is then creating a shadow image of the specimen using the residual radiation. The different shades of gray of the shadow images represent the differences of the wall thickness of the specimen. Defects, such as air inclusions, have lower absorption and are visible as bright spots.

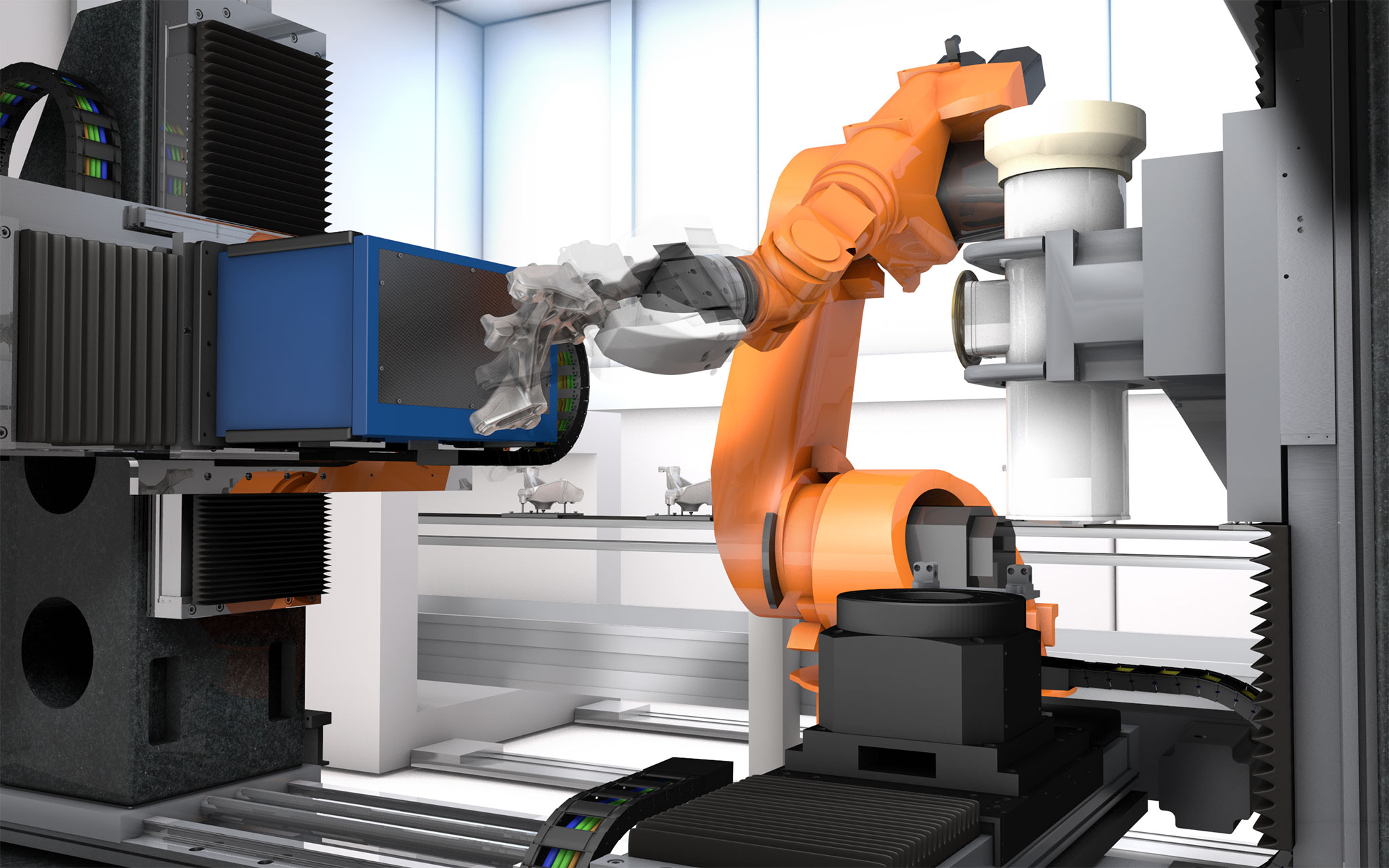

In fully automated inline X-ray inspection, test objects are automatically positioned using a manipulation system and image data is automatically generated. This data is then evaluated with software for automatic defect recognition (ADR software). Based on defined criteria, detected defects are evaluated and the test samples are automatically rejected on the basis of this evaluation or handed over for further processing.

Fraunhofer EZRT is offering a complete package for fully automatic inline X-ray inspection with the software solution ISAR. From the fully automatic evaluation of X-ray images of the components to the monitoring of production.