Small-angle X-ray scattering (SAXS) is a non-imaging analysis technique that uses X-rays to characterize materials. It is most commonly used when conventional imaging methods such as radiography or computed tomography are incapable of capturing tiny structures in the nanometer range. SAXS makes it possible to obtain valuable measurements and statistical information without elaborate image processing. In this way, the technology can also improve the safety and performance of batteries. How exactly does this work? To find out, we talked to Dr. Bernhard Schummer from the Development Center X-ray Technology.

Small angle, big effect – Small-angle X-ray scattering in battery research

June 17, 2024 | Assessing battery safety and performance

Dr. Schummer, small-angle X-ray scattering sounds like a complex technique. What is this technology used for?

Small-angle X-ray scattering, or SAXS for short, is used mainly in basic research. Without this technology, we wouldn’t be able to glean any information about the structures of nanomaterials located within a surrounding medium such as a solution. This is also a hugely important technology in research and development generally – including with regard to battery research and to sustainable electromobility in particular.

A major topic for the Development Center X-ray Technology. How can SAXS help achieve sustainable electromobility?

When it comes to developing batteries, the right combination of materials is essential for both safety and performance. Batteries need to be stable and must not swell. Their capacity should remain as constant as possible for a long time. If a battery loses its capacity too rapidly, it’s important to discover why. At the nano-level, batteries have pores through which electrons and ions pass from material to material. To ensure normal function, these pores must remain open.

According to scientific research, blocked pores can result in dwindling capacity. But how do we find out if this is indeed the case?

Typically, tests are performed on simple button-cell batteries during predevelopment. One option at this point is to open up the battery and look inside using an electron microscope. Unfortunately, in addition to destroying the battery itself, this alters the layers and material structures. Moreover, only a small section is visible at a time. But with SAXS, we can leave the button cells intact and examine a larger area in one fell swoop. SAXS is also a reliable method for measuring changes in pore size. Its main benefit, though, is tracking the battery’s charging and discharging processes in situ.

What’s more, lithium nanoparticles – which are commonly used in batteries – have the tendency to swell or even degrade after a number of charging cycles. The size of the particles should remain largely the same, however, and a shift of just a few nanometers can make a big difference. Such changes are easy to overlook when using conventional methods, but we have reliable ways of detecting them.

That sounds like quite the leap forward in quality for battery development. But how does the technology itself work?

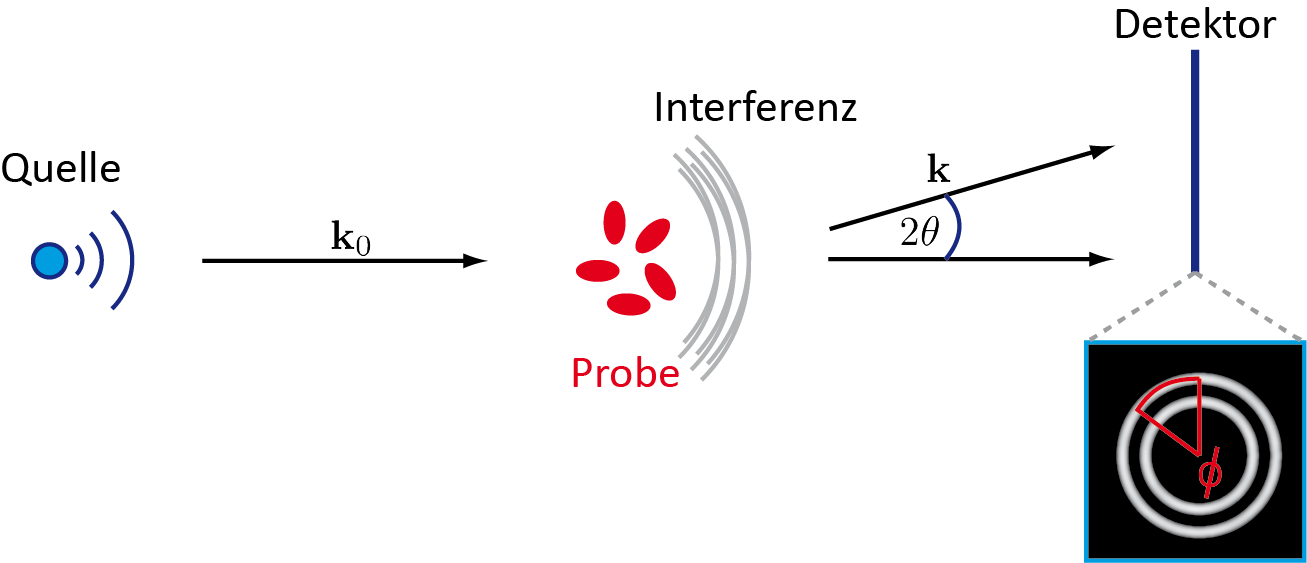

Simply put, SAXS measures how the angles of the X-rays change when the rays encounter an object. The physics of it is that X-ray photons react in different ways as they pass through matter. Sometimes the photons retain their energy, sometimes they lose energy. In the case of SAXS, only photons that don’t lose energy are scattered at small angles, hence the name. The only way to measure the scatter at all is to use a monochrome X-ray beam – in other words, one with a single wavelength or frequency.

After the X-ray has penetrated the sample, it hits a flat detector that measures the intensity distribution. Our next step is to take a closer look at the scatter pattern we see there. Finally, we use mathematical calculations to model particle size and shape, as well as the material’s density and sometimes even its structures. This allows us to examine all kinds of materials with a range of less than 150 nanometers.

What are some of the other applications for SAXS?

SAXS is generally suitable for studying any material with nanostructures. Today, more and more materials are being deposited on electronic components via printer. Liquid metal ink, for instance, is used to lay down conducting paths. Working with certain metals such as gold or silver can get expensive really fast if you end up with the wrong size of particle. In such cases, SAXS-based monitoring would quickly pay off.

Among the most interesting applications are nanometer-scale samples located in solutions. No other established method, including electron microscopy, can be used to collect data on the size, shape, and density of samples in the desired medium. This is because samples must first be dehydrated in order to measure them in a vacuum.

How might customers implement SAXS?

SAXS can be easily integrated into the production process as a means of live monitoring. It’s also an important tool in the development of new materials when nanometer-scale structures need to be mapped. At the Development Center X-ray Technology, we have the advantage of being able to tailor this technology to each customer’s specific requirements.

Dr. Schummer, thanks for talking to us.

Interview conducted by Lucas Westermann, editor, Fraunhofer IIS Magazine